WELLINGTON COUNTY – April showers in sugar bushes are a little sweeter this year.

It’s been seven weeks since trees were first tapped in Wellington County and still sap drips from tips of maple tree branches like sweet rain in a mild afternoon sun.

Anything would be an improvement over last year’s blip of a season, but it seems Mother Nature has found her sweet tooth once again over the winter.

“Last year was the worst year in 50 years, right across the board,” said Fred Elliott of Elliott Tree Farm, a small 130-tap operation near Hillsburgh.

“It was warm and sap went up the trees and stayed up the trees.”

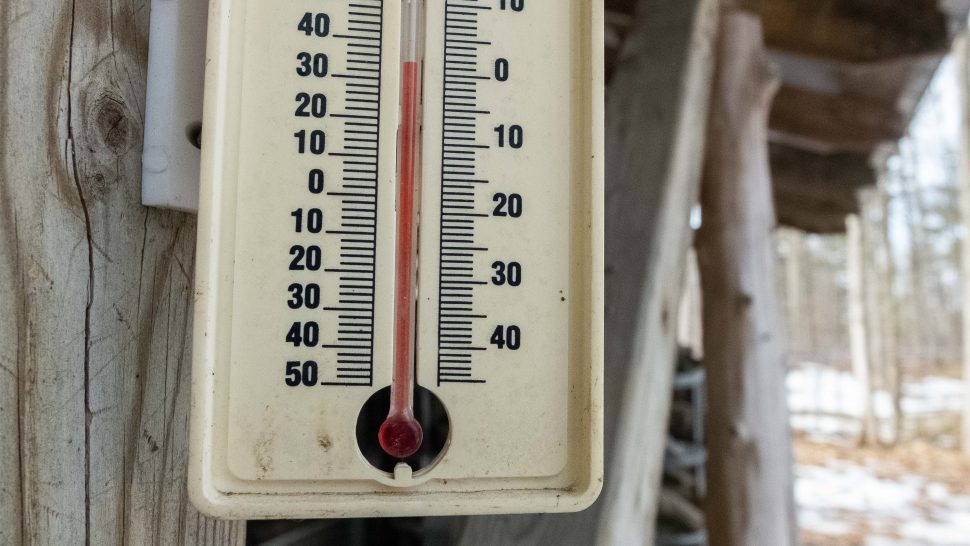

Pressure changes within a tree from day and night temperature swings, as winter fights for a hold over the softening of spring, causes sap to travel up and down a tree’s sapwood.

Once warmer weather takes over and the freeze-thaw cycle stops, trees begin to bud and the maple syrup season comes to an end.

“The last week we’ve not been able to cook it fast enough,” said Derek Elliott, Fred’s son, who now looks after the Christmas tree farm.

“Last year was one of our slower seasons and this year’s one of the busiest,” Derek said.

Some years at the multi-generational Kallonen Maple Farm in Puslinch, the sap is running from the tree by the time a hole is drilled during warmer years.

“This is probably a much more traditional syrup season,” said Alison Nugent, who oversees marketing and the business side of things at Kallonen, a 2,000-tap sugar bush linked by tubing and a vacuum pump.

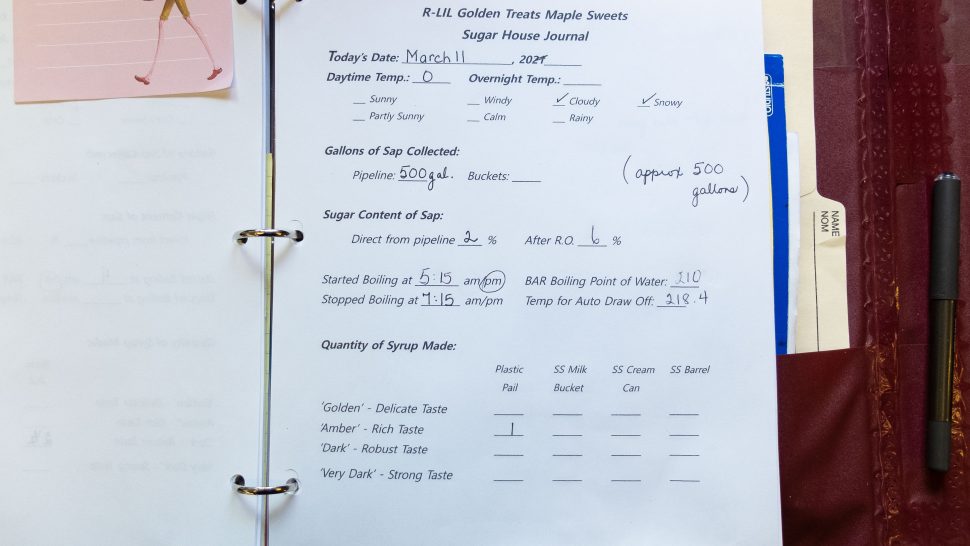

When winter is overcome early, a sugar shack may only see eight boils – as was the case last year at Yungblut Maples, a family-run operation near Palmerston.

In 2021, the Yungbluts managed 700 litres of maple syrup from 1,300 taps on the property.

Once the weather warms and trees begin budding, the sap becomes milky and goes off-flavour, explained Don Yungblut.

This year, only their second operating, Don said the family has boiled 17 times, yielding between 1,400 and 1,500 litres of finished product.

“It’s been a very good season,” he said.

Between 96 and 99 per cent of tree sap is made up of water. Getting the liquid gold many enjoy on pancakes is an intensive process requiring a lot of heat and time.

Generally, producers need 40 litres of tree sap to get one litre of maple syrup.

Modern operations, such as the Yungbluts, use reverse osmosis to reduce a percentage of the water before boiling, saving time in the evaporator.

As the water evaporates, producers are left with less liquid volume and a thick syrup made sticky and sweet by a significantly higher sugar concentration.

The sweet spot: 66 to 68 per cent brix content, or the sugar content measured in a liquid.

On April 10 the Elliotts were hosting their last group tour before collecting the day’s plentiful run from buckets and boiling late into the night with another round planned for Monday – likely to be the last of the season.

“Over a six-week season, we’ll collect 5,400 litres out of this bush, one drop at a time,” the elder Elliott said.